Slab Formwork in Construction

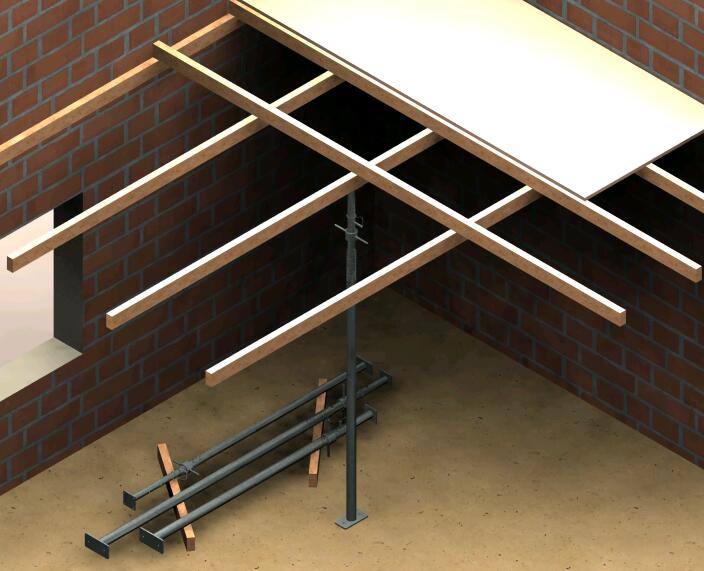

For the roof pouring is needed the formwork which is supported by props. The formwork is a bearing structure, which must be able to carry the uncured concrete mass, until it self has come to be supporting. The system in the image consists of prefabricated formwork timber and steel props. The formwork is typically set by hand and clipped, or screwed together. The advantages of a system are: does not require a crane to place the formwork, speed of construction with unskilled labor, formwork modules can be removed after concrete sets leaving only beams and steel props in place prior to achieving design strength.

Slab formwork consists of the plywood surface against the concrete, which is often plywood, boards, or form panels. The plywood surface is supported against the supporting rails, which are usually 50 x 100 timber. When technical work, such as bridge construction is also used for heavier timber. Battens come under the neck, which are 50 x 100 or 50 x 200 timber. The location is perpendicular to the floor joists over.

15,5 kN ... < 3 m Steel prop

22 kN .... < 3 m Steel prop

22 kN ... < 4 m Steel prop

For example steel props can be used to support the roof under snow. About two thousand kilograms of strength and good extension, is useful for many tasks. As a product, props are under the compressive load.

21.6.2018*8:00 (43923 - 114)

www.karikolehmainen.com

epcalculation@gmail.com

|