Other Products

1. Lugs to Lifting Beams

2. Element Moulds to Factories

3. Service Platform Design

4. Dock to the Inland Waters

5. Mechanical Pipe Fittings

6. Crane Hatch Mechanism

7. Pile Turners

8. Portable Gantry

9. Semi-Goliath Crane

10. Goliath Crane

11. End Carriage - Cross-Section

12. Underhung Crane

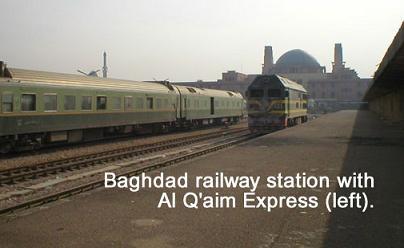

13. Railway Buildings in Irag

14. Bridge Elements for Vehicles

15. Screw Conveyor as a Product

16. Screw Conveyor in the Product Value Space.

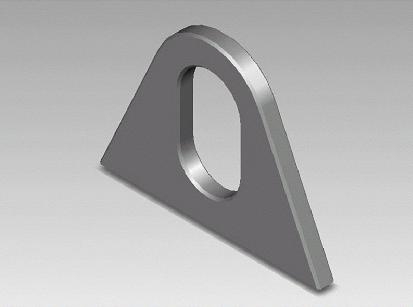

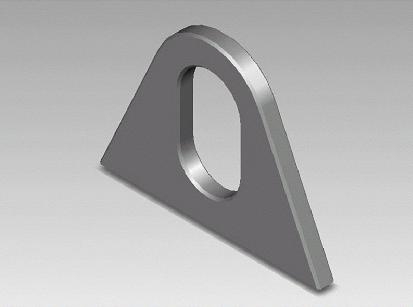

1. Lugs to Lifting Beams

Lifting lug of steel is visible and hand-touchable. The lug conveys the force from the hook to the lifted body. The lifted weight cannot see, but it can calculate. When lifting, the weight converts to potential energy. The energy used to lift process and it consists of potential energy and machinery losses.

The deformation of the lifting lug is proportional to lifted weight, without telling the amount of the used power. This is because, by knowing the power in time unit, the total time or lifted height is not known. Time does not affect to strength of the lifting lug. It is affected by the number of repetitions. On the other hand, repetions can not determine by examining the lug.

History backwards: The Big Bang generated 80% hydrogen and 20% helium. Percentages should pay attention to, because this ratio affects a number of issues. For example, the ratio of right and left-handed people. As an introduction to the factor of 1.25, in general 20 % corresponds to 80 % of all events.

100/1.25 = 80 40/80 = 0.25

The collapse of stars generated nuclear fusion and new elements such as iron and is therefore everywhere in the universe. Iron is a chemical element, including the mathematical proportionality. The calculation is based on the S235 and S355 strength class steels, which closely have the strength ratio of Golden Ratio 1.618. Calculated ratio S355 / S235 = 1.51

It is good start the design work by planning first the lifting lugs. Once I heard the supervisor's instruction, at a tank manufacturer's premises; "do first the needed lifting lugs". This, because a designer had forgotten lifting lugs. The problem was how to turn the tank construction, without lifting lugs. Previous sounds humorous, but think it more about. (978)

2. Element Moulds to Factories

Two to Irak delivered mould equipment and participation to design. Tens of moulds to build towns. In the picture poured column mould and behind other moulds to different intention. Installation made by men, who made moulds in Hollola factory in year 1981. The starting-point to design were drawings and requirements of flatness on the surfaces and straightness.

Dry and warm environment does not demand the erection of structures on top of the moulds. Sandstorms only can cover moulds to dust and sand. For the most difficult moulds have indicated to be the spiral stair moulds. These drafting by hand to paper produced gray hairs and worry. The definition of the strength calculation are increased eg. initial stresses' and noticing the mould pressure effect. Later different vessel constructions and measurements have learned, the stiffened sheet fields are more rigid, than by calculating. In this context I write about mild steels. When non-corroding stainless steel, there is cold reduction effect, which I write in related to vessel structures. (935)

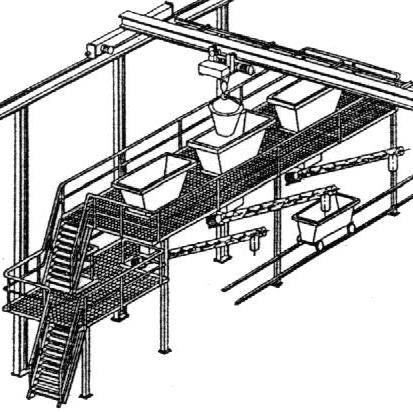

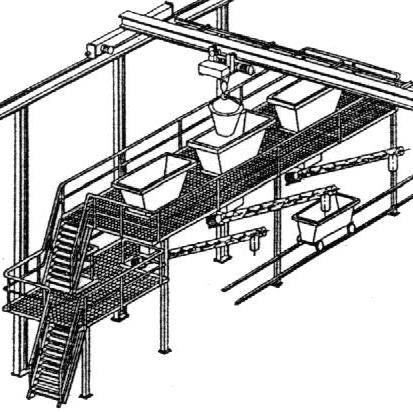

3. Service Platform Design

The constructions are designed in accordance with the site, proportionality is contained in them. The weight of the structure is often determined in advance, in which case the method is useful for calculating the offer. Stairs are also possible determine according to Pascal's triangle.

These pages describe the determination of vertical rise and horizontal thread ==> of the stairs. Whenspreadsheet calculation, stairs are the task run, without the concept of proportionality. By knowing both ways, this is useful for many sense. (940)

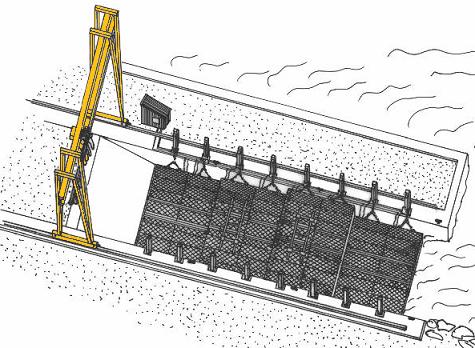

4. Dock to the Inland Waters

With compressed air and help of the water pumps, working special solution. The construction was progressive and reasonable make, with the intention to use recirculation materials. The town did not come along as being concrete structures manufacturer, whereby project expired.

Floating dock

Dock had state of readiness to lift a car ferry, the weight about 150 000 kg. The vessel, which especially was thought to this dock, was one winter in one canal on the wooden posts. Experiences of this was not encouraging. Canal lockgates leaked water, whereby pumping equipment and their working expenses were huge. Instead of the dock, was completed slipway hoist for the marinas. (934)

5. Mechanical Pipe Fittings

D42 - D48 Tubes

Why to weld the service platforms, if the sturdy structure can be made without welding? I have measured these kind of structures, at the same time heard of their high design and manufacture cost. I do not see the difficulty to solve this, because the strength of a railing has a little to do. Some of the rails at the moment have pop rivets, and I do not mean this kind of fastening. Aluminum rivet can corrode and cause danger.

The tube structure has an empty interior and there is a place to connecting part. This we cannot see inside the tube. Installation does not require welding, wherein installation is fast. The upright post tubes can be attached by the same way, with a special attachment. Stainless steel tube accessories can bring in loose parts to assembly site, which requires the tube cutting for mounting. Black pipes are painted prior to delivery, or they can be painted upon installation. Delivery method is, of course, a proprietary to the product. The outcome in both scenarios are neat and review-proof. (952)

6. Crane Hatch Mechanism

Crane hatch makes it possible to run a bridge crane out of the inside hall. Parts made the metal department of the Vocational School. At the late spring time, parts was finalized by Lahti Adult Vocational Training Center. I got the design to be done, because I had designed cranes and also the crane in the hall was partly my design.

A visible air gap at the upper edge

The problem of the hatch, is the incorrect hinging position and not compressing the bottom edge. In the photo, there is an apparent air gap at the hatch's upper edge. Comparable air gap is also at the hatch's bottom edge. The fault was in earlier design, never got completely eliminated. The hatch has three lifting wires. This because the hatch is wide and construction is a quite light. Do we learn something of this kind of design? Yes, all experience complete the each others. One note. The design of the crane hatch is not mine. (937)

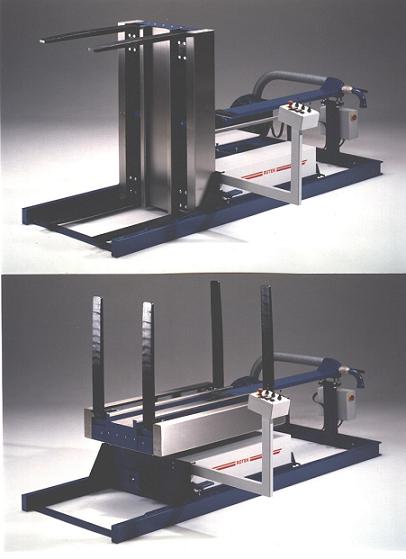

7. Pile Turners

In the 80's the Finnish company had a claim to being the pile turner manufacturer into a must-have item on every printing house floor. Later Rotek pile turners were globally well known brand among paper sheeting. These products were the first hydraulically-operated appliances. At the beginning the competitors argued by claiming that who wants on the floor an oil leaking device. Today all want, contrasts to huge sized mechanical devices. A part of before mentioned is from the Internet.

I did the modernisation design to these products and sold the products to agents of different countries and after sales operations. After years of effort, an indication of the well-known brand continues to warm up my mind. (942)

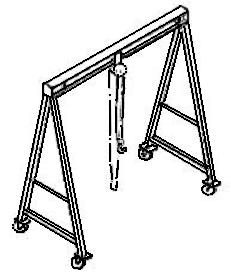

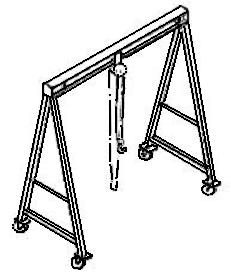

8. Portable Gantry

These are light and can be dismantled, and rapidly put into operation. Portable gantries are generally used with a manual chain hoist for assembly and maintenance operations.

Construction: fabricated in steel. The primary structure is rigid, using closed pipe profiles and attaching the hoisting mechanism onto a suitable I-profile. Hoisting capacity in this type product is usually 500 - 1000 kg. Nothing in any case prevent from making a larger gantry.

Runners: of large diameter, in highly resistant nylon, cast iron or rubber, mounting on pivoting ball-bearings. Usually two wheels are equipped with brake.

Movement: In principle, the goliath should remain immobile when loaded, as it is intended for lifting rather than handling operations. However, it is possible to move a loaded crane, provided the precaution is taken of lowering the load almost to ground level in order to avoid overturning the goliath. (964)

9. Semi-Goliath Crane

The semi-goliath crane is recommended when the structure is unable to support a gantry, or a runway is only one side of the building. Semi-goliaths for Equivalent Proportional Calculation are up to 10 tonnes, 18 meters.

The construction is the same as is used manufacturing goliaths. Hoist unit has a cover to protect the machine from the weather if located outdoor.We study the structure of the product and the weight formation.

Standard long travel speeds:

In single speed: 20 m/min or 30 m/min

In dual speed: 20 and 5 m/min or 30 and 7,5 m/min

Special equipment for hydraulic motions to ensure infinitely variable speed, prevent load swing and to give greater safety and precision of handling.

Flexibly tyred runners with hydraulic travel, when the ground is sufficient flat and capable of supporting the direct weight of the runners. Parking devices, for exterior use.Travel limit switches and automatic safety stopping device. (939)

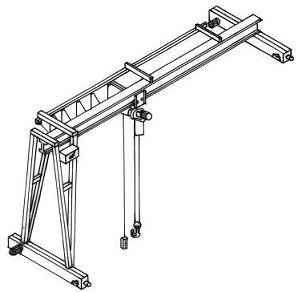

10. Goliath Crane

Goliath cranes are modifications of travelling cranes and are used essentially outside where it is not convenient to erect on overhead runway, or in building of light construction. Goliath cranes for EP-calculation are up to 10 tonnes, 18 m.

Drawing of an inland water dock project

Goliath cranes can be broken down into 4 principal elements

The main girder or girders: in standard rolled sections, or of welded box construction, according to the load capacity and span of the crane.

The legs: in machine welded steel sections, or of welded box construction, ensuring main girder end carriage rigidity.

End carriage; End carriages (or wheel blocks) of Equivalent Proportion Calculation are standard design. In machine welded steel sections (recommendation), including all the mechanical items: runners (in steel, mounted on ball or roller bearings), geared motor units (single or dual speed, which are left-handed or right-handed construction combinations), rubber buffers and control panel etc.

Lifting unit:

A cover to protect the macine from the weather is often used.

Travel speeds for guidance:

In single speed: 20 m/min or 30 m/min

In dual speed: 30 m/min and 7,5 m/min

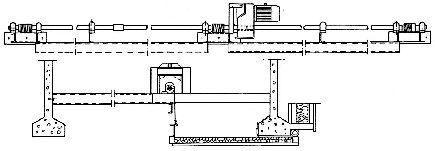

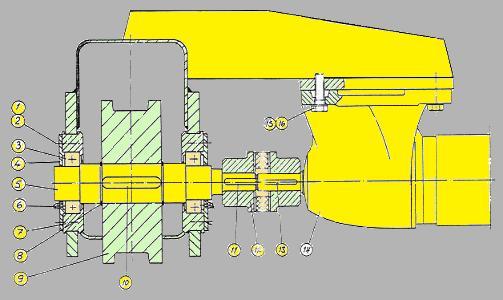

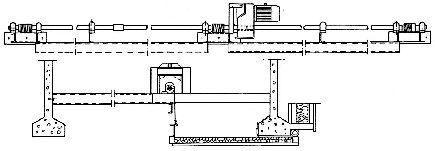

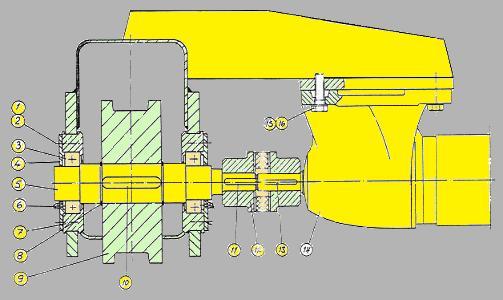

11. End Carriage - Cross-Section

The end carriage in the image, is an example from the 80's. Direct drive flange wheels with ball bearings. Not open gear as the models have in calculation.

The drawing shows a simple structure of a crane. That which must be able to, is to calculate the strength of the structure, wear of the running wheels and the appropriate driving output. Today the structure is different from the images shown, but the structure of the cranes are still in use. The specialty of the bearings is a bearing housing which is made of two parts. As a result, the bearings and the running wheel is easy to replace when needed. (944)

12. Underhung Crane

5 t crane, Lahden Lämpövoima Oy, Lahti

The crane is located at the coal field maintenance facility, there to lift machinery parts.In its simplest form the bridge consist of an I-beam frame supported by eight wheel, a pair of wheels at each corner, which are on the lower flange of I-beam rails. The crane is moved by hand chain turning sprocket wheel, which is keyd to shaft. The pinions on shaft mesh with gears, keyed to the axles of two wheels. Runners are mounted on ball bearings, removable axles and runners shaped to run on all types of monorail sections. (936)

Up to 18 meters at 5 tons (moved by electric motors)

Special constructions made of stainless steel

13. Railway Buildings in Irag

http://www.on-track-on-line.com/foto-iraq.shtml

Iraqi railway station modernization of buildings, mold equipment design. Irregular shape of a roof, shown in the form of a function. (938)

14. Bridge Elements for Vehicles

The Equivalent Proportional Calculation is mathematics and a study of the matter and forces inside the matter. I explain how the forces are the same outside the material? I did start design having drafting machine and paper, later two-dimensional Cad-programs and finally three-dimensional programs. The first photo of the these products has taken by my film camera about 30 years ago. Forces in the matter and the material as steel stay.

Bridge elements for city utility works. These elements are an economical and flexible way for vehicles guidance over open canals. Using elements, canal can stay open over night or week-end without traffic or safety troubles. The photo has taken 01.05 2008.

Construction

Tear plate surface with the steel box stiffeners. Each element width of 1220 mm are connected together using fixing devices. Rails are made of round steel pipe and are equipped with kicking boards. In the middle stiffenener there is a place for user's name. Normally, the name of some company. Holes for rails and fixing devices works as lifting lugs while mounting or dismounting. Grey paint finishing.

Use of Elements

Elements are rapidly mounted from truck's bed. After assembly, elements work as well in sommer or winter like environment. When storaging elemets, they are possible to place side by side and put one on top of another. By this way, they do not take much pace.

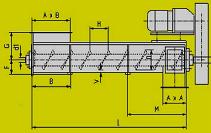

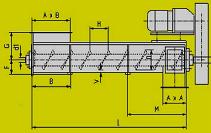

15. Screw Conveyor as a Product

Technically screw conveyor is simple and cheap, but harmful aspect is the wear and power demand putted in proportion to the material amount. The capacity of the conveyor is generally 5 - 40 m3/h , whereby the larger conveyors can be over 200 m3/h. On the big material flow, other conveyor solutions come often more reasonable. Technically screw conveyor is simple and cheap, but harmful aspect is the wear and power demand putted in proportion to the material amount. The capacity of the conveyor is generally 5 - 40 m3/h , whereby the larger conveyors can be over 200 m3/h. On the big material flow, other conveyor solutions come often more reasonable.

The buoyancy force of the screw conveyor in the Product Value Space

Modell of the Calculation

The calculation gives a model, how the data known of the conveyor, is comparable to other similar conveyors data. For example knowing the weight of the screw conveyor, this is changed for the comparable conveyor values. Supporting length can grow or be shorter and so on. We calculate all conveyors in series and in addition to this we study exceptions. The accuracy of the calculation is under 5 percent.

Alternative defining way

Without EP-calculation, can calculate power and the capacity for the conveyors. The weight defining is more difficult. How many controls this task? With the help of the EP-calculation, all control this. The calculation is being ensured by comparing the data of the conveyors to data of product deliverers about the products. In addition to this, is in use a calculation program, based on to the standards and to experiences of the conveyors. Flattening the screw is one of the screw conveyor associated task. We study a way to flatten the screw correct. Some literature given pattern make the disk part incorrect sized. (931)

16. Screw Conveyor in the Product Value Space

I am listening the marketing man of the productization, when the sentence falls on the ear: When the first product, it has to think whether more models and where in the product space, is located. This is like the introduction to the Equivalent Proportional Calculation, which has as many spaces as products. I am listening the marketing man of the productization, when the sentence falls on the ear: When the first product, it has to think whether more models and where in the product space, is located. This is like the introduction to the Equivalent Proportional Calculation, which has as many spaces as products.

For example, screw conveyors to wood chips and conveyors to rock material have their own product spaces. This is because the latter products are constructed against wearing and have a stronger construction.

Let us imagine the screw conveyor is located into the product value space. It seems affected by gravitational force, minus the centrifugal force of the Earth's rotation. There remains the gravity g of 9.82 m/s2. Second square (m/s2) is an interesting note of the surface area. It has a result as a buoyancy force, because the surface area is subjected to pressure. Calculated values of the conveyor rise up, such as a submarine in the photo. The idea Archimedes discovered in his own time, located to the present day.

21.6.2018*8:00

www.karikolehmainen.com

epcalculation@gmail.com |

Technically screw conveyor is simple and cheap, but harmful aspect is the wear and power demand putted in proportion to the material amount. The capacity of the conveyor is generally 5 - 40 m3/h , whereby the larger conveyors can be over 200 m3/h. On the big material flow, other conveyor solutions come often more reasonable.

Technically screw conveyor is simple and cheap, but harmful aspect is the wear and power demand putted in proportion to the material amount. The capacity of the conveyor is generally 5 - 40 m3/h , whereby the larger conveyors can be over 200 m3/h. On the big material flow, other conveyor solutions come often more reasonable.