Missing Moment of the Wire

The thin wire is placed between two points, which represent the points A and B. The wire can be expected to be light, wherein the supporting forces A and B are small.

A = B = G / 2

So that the light wire does not have any sag, there is need to have an infinitely great force, relative to size of the wire. The strength of the wire will, therefore, be extremely large in order to take against the pulling force. This situation does not arise in real life. A similar kind of situation still is generated by electrical power lines with wire sagging. The thin wires are under tensile stress, but having no bending moment. Wire as a result of lack of rigidity, the wire dimensioning is based on the cross-sectional surface area. So that the light wire does not have any sag, there is need to have an infinitely great force, relative to size of the wire. The strength of the wire will, therefore, be extremely large in order to take against the pulling force. This situation does not arise in real life. A similar kind of situation still is generated by electrical power lines with wire sagging. The thin wires are under tensile stress, but having no bending moment. Wire as a result of lack of rigidity, the wire dimensioning is based on the cross-sectional surface area.

In a cross-section with a small section modulus, tensile stress arises in practice. Wire and electric wire rope, have a poor load bearing capacity, not to mention of the pushing, but a large pulling capacity. Pulling forms a tensile stress, whereby the wire dimensioning is a quite simple task.

Pieces having a stiffness => generate a tensile and compressive stress which have opposite signs on opposite sides of the cross-section. In the center is the neutral axis, where the stress is zero.

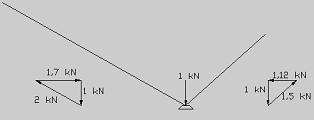

When suspending the roadway lighting eccentrially, it generates the above loading case. Designer's design program makes the determination of forces in the wires to be simple. After this is determined an appropriate safety factor for cable pulsating loads. When suspending the roadway lighting eccentrially, it generates the above loading case. Designer's design program makes the determination of forces in the wires to be simple. After this is determined an appropriate safety factor for cable pulsating loads.

Outdoor lighting collects snow and wind waves the whole etc. This is taken into account, in particular at the ends of the wires in the fastenings of the structures. Furthermore, taking into account the wire shackles number of connection points. At least two wire shackles, and taking account the effect of the corrosion to wire. A simple design includes a number of things to consider, so that the designer can sleep with peace of mind the night.

The calculation of human fatigue, the steel girder bending and many things are synonymous. If the girder is placed on top of a larger load => increases the deflection of the girder. If a man is set to bear a greater burden => increases the spent performance time. The used time has the same meaning in terms of fatigue, because fatigue increases time. The athlete's fatigue level may partially determine by the basis of the time. On the other hand, if the girder length is increased while maintaining the same load => growing even in this case the deflection of the girder. In human cases the increasing distance => increases execution time (used time). These things are clear concepts, without counting the associated same meanings.

Time comparisons, it is often a one-dimensionality. Interestingly, the road running time consists of the time arised through all dimensionalities (up and down - left and right - time (dilation). The wire movement is forward and back, the pulleys conveying the movement through the dimensionalities. Rigid steel bar in place of the service; does not own the thread-like property of matter. Thread (wire) and its design is not essential, but the lack of reference to the thread moment (torque). The matching situation arises in connection with running, where the missing moment does not preclude different dimensionalities. This is calculated, the physics and physiology having the same notes. This will be discussed soon in the form of calculation.

9.5.2015*17:40 (1091 - 306)

www.karikolehmainen.com

epcalculation@gmail.com |